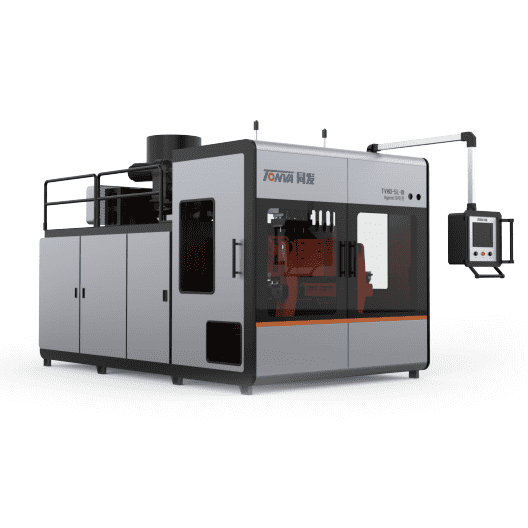

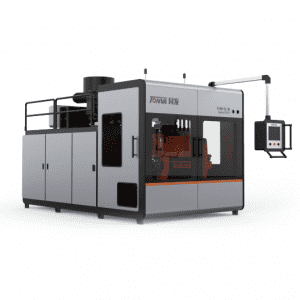

Kev xaiv loj rau HDPE Yas Fwj Extrusion Tshuab Moulding Tshuab Ua nyob rau hauv Suav teb

Peb ib txwm tsis tu ncua muab koj nrog qhov tseem ceeb tshaj plaws kev txhawb nqa cov neeg yuav khoom, nrog rau ntau yam kev tsim thiab qauv nrog cov khoom zoo tshaj plaws.Cov kev sim no suav nrog qhov muaj cov qauv tsim tshwj xeeb nrog kev nrawm thiab xa mus rau Kev Xaiv Loj rau HDPE Yas Fwj Extrusion Tshuab Moulding Tshuab Ua nyob rau hauv Suav teb, Ntawm tus account ntawm superior zoo thiab kev sib tw muag tus nqi, peb yuav los ua tus thawj coj ua lag luam tam sim no, nco ntsoov. kom tsis txhob tos tiv tauj peb ntawm lub xov tooj ntawm tes lossis email, yog tias koj txaus siab rau ib qho ntawm peb cov khoom.

Peb ib txwm tsis tu ncua muab koj nrog qhov tseem ceeb tshaj plaws kev txhawb nqa cov neeg yuav khoom, nrog rau ntau yam kev tsim thiab qauv nrog cov khoom zoo tshaj plaws.Cov kev sim no suav nrog kev muaj cov qauv tsim kho nrog kev ceev thiab xa mus rauTshuab Moulding Machinery, Tuam Tshoj Yas Tshuab Tshuab, Txij li thaum tsim peb lub tuam txhab, peb tau pom qhov tseem ceeb ntawm kev muab cov khoom zoo thiab cov kev pab cuam zoo tshaj plaws ua ntej muag thiab tom qab muag.Feem ntau cov teeb meem ntawm cov neeg muag khoom thoob ntiaj teb thiab cov neeg siv khoom yog vim kev sib txuas lus tsis zoo.Kev coj noj coj ua, cov neeg muag khoom tuaj yeem tsis kam nug tej yam uas lawv tsis nkag siab.Peb rhuav tshem cov teeb meem no kom ntseeg tau tias koj tau txais yam koj xav tau rau qib koj xav tau, thaum koj xav tau.

TECHNICAL SPECIFICATION

| Qeb/类别 | Yam khoom/项目 | Chav tsev/单位 | 1L | 2L | 3L | 5L | 12 L | 20 L | 30 L |

| Basic Specification 基本规格 | Raw Khoom / 材料 | — | PE / PP / PA / PVC thiab lwm yam | PE / PP / PA / PVC thiab lwm yam | |||||

| Dimension / 机器外开?尺寸 | m | 2.7 × 1.6 × 1.9 hli | 3.1 × 2.0 × 2.0 | 3.2 × 2.0 × 2.0 | 3.5 × 2.1 × 2.1 / 3.7 × 3.0 × 2.1 | 4.3 × 3.5 × 2.2 / 4.6 × 4.4 × 2.2 | 5 × 5.9 × 2.35 / 5 × 6.5 × 2.4 | 53 × 6.4 × 2.4 hli | |

| Total Weight/机器重量 | T | 2.3 ZPO 4.2 | 3.2 ZPO 6.5 | 3.4 ZPO 6.8 | 4.878.5 ib | 12/13 | 17/18.5 Nws | 20 | |

| Extrusion System yog tsim los ntawm cov khoom siv hluav taws xob | Ntsia Hlau Tsav / 螺杆电机 | KW | 7.575.5 ib | 15/7.5 Nws | 18.5/15 Nws | 22/18.5 | 30(37)/22 | 55/37 ib | 75/55 ib |

| Txoj kab uas hla ntawm cov ntsia hlau / 螺杆直径 | mm | 55/45 ib | 65/55 ib | 70/65 ib | 80/70 ib | 90/80 ib | 100/90 | 110/100 ib | |

| Ntsia Hlau L / D piv / 螺杆长径比 | L/D | 23: 1/23: 1 | 25: 1/23: 1 | 23: 1/25: 1 | 23: 1/23: 1 | 25:1 (28:1)/23:1 | 28: 1/28: 1 | 28: 1/28: 1 | |

| Extruder cua sov fais fab / 螺杆加热功率 | KW | 7 | 15 | 18 | 20 | 23 | 28 | 30 | |

| Tus naj npawb ntawm cua sov zones / 螺杆加热嬲 | pcs | 3 | 3 | 3 | 4 | 5 | 7 | 8 | |

| Plasticizing muaj peev xwm / HDPE 挤出量 | kg/h | 55 | 70 | 75 | 95 | 120/130 ib | 160 | 180 | |

| Tuag Lub taub hau 模头 | Cua sov zones / 模头加热段数 | pcs | 3-5 | 3-7 | 3-7 | 3-9 | 3-12 | 3-11 | 3-5 |

| Cua sov zog / 模头加热功率 | KW | 1.5-3 | 2-4.5 | 2.5-5 | 3-6 | 5-9.5 Nws | 8–14 | 10-12 | |

| Tus naj npawb ntawm kab noj hniav / 腔数 | — | 1-4 | 1-6 | 1-6 | 1-7 | 1-10 | 1-5 | 1-2 | |

| Clamping System Cov khoom siv | Sliding nrug / 移模行程 | mm | 300 | 360/400 ib | 360/400/450 | 450/550 | 600/650/700/800/850 | 700/800/850 | 800/900 |

| Clamping nrug / 合模行程 | mm | 150 | 200 | 200 | 250/200 | 350/250/200 | 350/250 | 400/350 | |

| Qhib stroke / 开合距离 | mm | 160-310 : kuv | 160-360 : kuv | 180-380/160-360 | 230-480/180-380/160-360 | 330-680/250-500/240-440 | 380-730/330-680/300-550 | 420-820/380-730 Ib | |

| Clamping quab yuam / 锁模力 | kn | 50 | 80 | 90 | 100 | 125/180 ib | 180 | 200 | |

| Kev siv hluav taws xob | Tag nrho lub zog / 机器总功率 | KW | 14-16/23-25 dr hab | 24-26/42-45 ib | 37-41/48-52 ib | 44^16/59-63 | 72-78 : kuv | 80-110 : kuv | 136-140 : kuv |

| Cua siab / 吹气压力 | MPa | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | |

| Huab cua noj / 耗气量 | m3/ min | 0.6/0.4 | 0.8 / 0.4 hli | 0.8/0.6 | 1/0.8 ib | 0.8 ua | 1 | 1.1 | |

| Dej siv / 用水量 | m3/ h | 0.6/1 | 1/1.2 | 1/1.2 | 1.2/1.5 | 1.5 | 2 | 2.2 | |

TECHNICAL SPECIFICATION

1.Tus naj npawb ntawm lub taub hau tuag thiab clamping stroke teev nyob rau hauv cov saum toj no yog teem rau cov qauv qauv.Lub peev xwm ntawm cov khoom hauv ntau qhov sib txawv ua rau ntawm ib lub tshuab yuav tsum tsis pub ntau tshaj qhov ntxiv lossis rho tawm 20% ntawm qhov pom zoo.

2.Ib lub tshuab, siv los tsim cov khoom uas muaj qhov ntau thiab tsawg thiab muaj peev xwm nyob rau hauv qhov sib txawv loj, tuaj yeem tsim nrog lub taub hau tuag hauv cov lej khib.Qhov kev tsim no ua rau nws tuaj yeem ua haujlwm rau ib lub tshuab hauv ntau txoj kev los ntawm kev kaw ib lossis ntau lub taub hau tuag.Siv lub tshuab "TVHD-1L-3" ua piv txwv, peb lub taub hau tuag rau 180ml lub raj mis thiab ob lub taub hau tuag rau 500ml lub raj mis.

3.Cov qauv saum toj no tuaj yeem hloov kho rau hauvaHom Hybrid ", lub tsheb thauj mus los yog tsim los nrog servo lub cev muaj zog kom ua tiav tsis muaj suab nrov, kev ua haujlwm yooj yim, txoj haujlwm meej thiab nrawm nrawm-ntsuas pwm.

4.Cov ntaub ntawv saum toj no tsuas yog siv rau kev siv xwb.Tonva tuav txoj cai hloov kho cov qauv siv tshuab.Cov khoom siv yuav raug tiv tauj.

Peb ib txwm tsis tu ncua muab koj nrog qhov tseem ceeb tshaj plaws kev txhawb nqa cov neeg yuav khoom, nrog rau ntau yam kev tsim thiab qauv nrog cov khoom zoo tshaj plaws.Cov kev sim no suav nrog qhov muaj cov qauv tsim tshwj xeeb nrog kev nrawm thiab xa mus rau Kev Xaiv Loj rau HDPE Yas Fwj Extrusion Tshuab Moulding Tshuab Ua nyob rau hauv Suav teb, Ntawm tus account ntawm superior zoo thiab kev sib tw muag tus nqi, peb yuav los ua tus thawj coj ua lag luam tam sim no, nco ntsoov. kom tsis txhob tos tiv tauj peb ntawm lub xov tooj ntawm tes lossis email, yog tias koj txaus siab rau ib qho ntawm peb cov khoom.

Kev xaiv loj heev rauTuam Tshoj Yas Tshuab Tshuab, Tshuab Moulding Machinery, Txij li thaum tsim peb lub tuam txhab, peb tau pom qhov tseem ceeb ntawm kev muab cov khoom zoo thiab cov kev pab cuam zoo tshaj plaws ua ntej muag thiab tom qab muag.Feem ntau cov teeb meem ntawm cov neeg muag khoom thoob ntiaj teb thiab cov neeg siv khoom yog vim kev sib txuas lus tsis zoo.Kev coj noj coj ua, cov neeg muag khoom tuaj yeem tsis kam nug tej yam uas lawv tsis nkag siab.Peb rhuav tshem cov teeb meem no kom ntseeg tau tias koj tau txais yam koj xav tau rau qib koj xav tau, thaum koj xav tau.